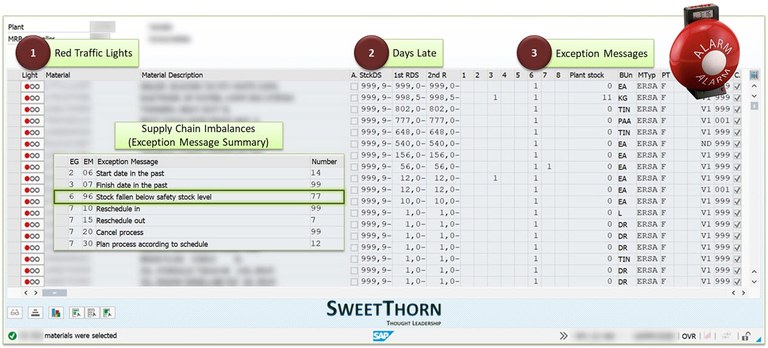

The alarm consist of 3 three things Sap does to draw your attention to the fact that you are into your emergency inventory:

- The SKU gets a red light

- Indicates infinitely negative days of supply (-999.9)

- Displays a 'below safety stock" exception message

By doing all of this SAP is urging your supply engine to react instantly to get your stock back to normal levels. It is a powerful way to avoid, and proactively manage stoppages caused by stock outs.

If your safety stock messages are high, a few things might be going on:

- You’ve had an unusual run on the SKU

- Your supplier or production has let you down

- Your safety stock setting is too high

- You do not know that you should be paying attention to these messages (especially if they’re as high as in the screen shot).

Some of my clients have had terrible experiences with safety stock and so just stop using it. The most common is an inflation of inventory levels and the other is being overwhelmed by too many exception messages. This does not need to be the case if a sound approach to developing your entire stocking strategy is followed. One that particularly that takes SAP’s other MRP settings into account, is well thought through, avoids one solution fits all, and is always, always exception managed.

You may want to read some other related blogs:

More about SAP's Supply Chain Exception Monitor

A graphically represented inventory optimization case study (with safety stock)