In my last blog I wrote about how you can use SAP’s stock graphs to show how inventory was spiraling out of control. In this blog I have used a graph as a case study to show how SweetThorn’s Supply Chain Coaching practices can bring about dramatic working capital improvement. It’s (almost) as easy as 1, 2, 3.

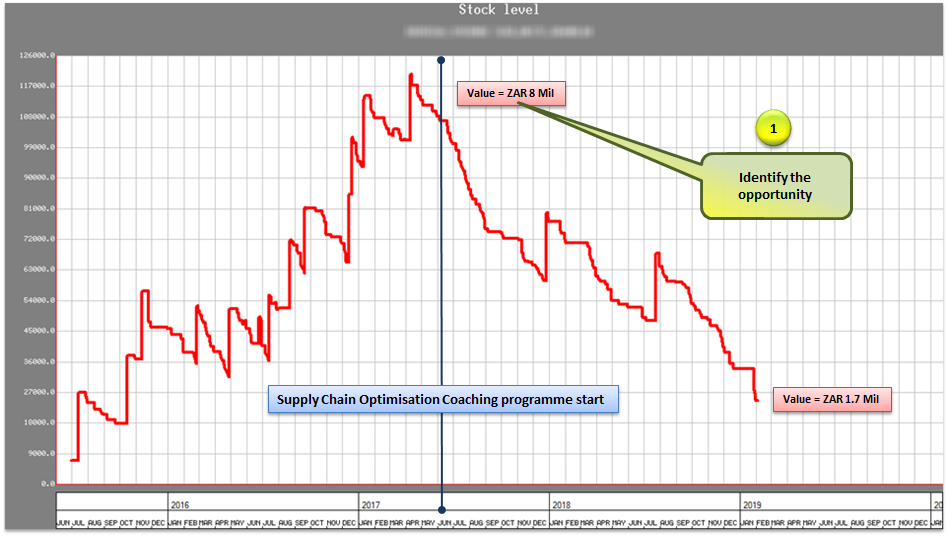

Step One: Identify the opportunity

At the start of the programme this graphic was used to engage the product owner with two simple questions: Why are we keeping so much? Is there something you know that SAP (and the supply chain) do not? Almost instantaneously, all orders existing orders were postponed as far out as possible. You’ll notice, after those questions were asked, that no stock was received for almost 6 months.

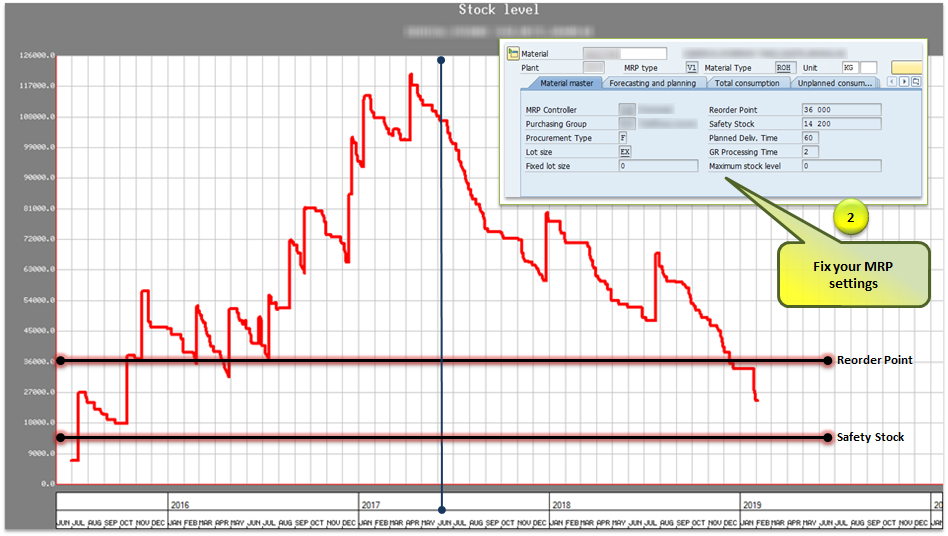

Step Two: Fix your MRP Settings

The next step in the Supply Chain Coaching Programme was to calculate and agree optimal stock levels, update the MRP settings and then to follow SAP’s replenishment prompts. The Optimisation Coaching Programme encourages a consultative approach to determine stock levels that are comfortable for all stakeholders. Any forced decisions will most likely jeopardize your ability to sustain working capital optimisation. Click here to read about what happens if you don’t get your MRP settings right.

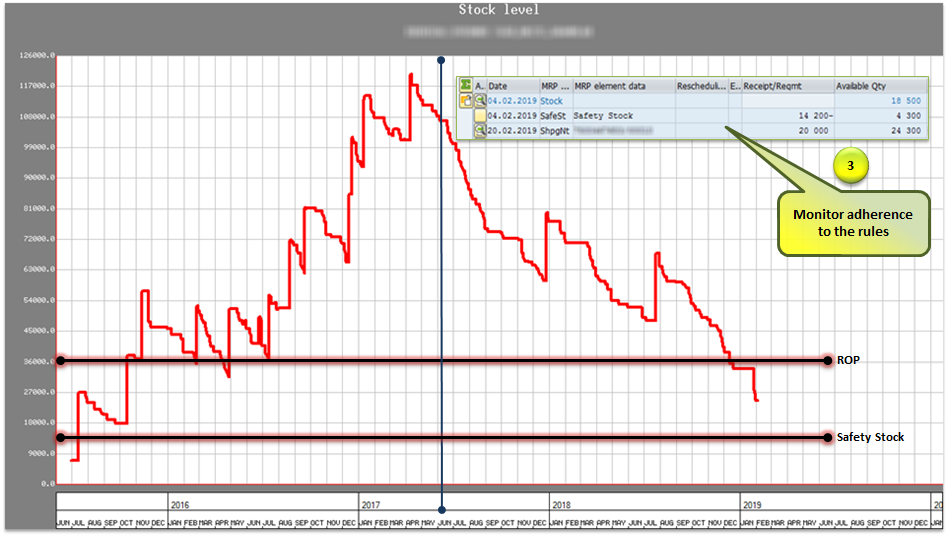

Step Three: Monitor adherence to the rules

Once the settings have been updated and the business rules agreed it is imperative that SAP’s Supply Chain Exception monitors are used to ensure that the stock levels are satisfying the needs and that the replenishment activities are being executed. This monitoring must happen everyday since optimisation efforts are thwarted exactly because the master data update is seen as a once off activity. Click here to see an example supply chain exception monitor.

These 3 steps need to become a way of life if you are to sustain your efforts.

Optimisation is a way of life, not a project

The steps described above cannot be seen as a once off event or project. We operate in a complex and ever changing world. And so the steps need to become a way of life. You do this by introducing daily activity that encapsulates “The Three Rs”: Rhythm, Routine and Real-time processing.

- Rhythm: A set time of day, every day, when your supply chain staff connect to ensure today's work will be done today.

- Routine: The steps and structure you will follow to ensure adherence the rules.

- Real-time Processing: Ensuring you data always reflects your current reality.

Originally published on Jan 28, 2020