There is no question that addressing the issue of material master data is complex and daunting, but you will have to begin somewhere. In the interests of getting back to basics, I’d propose you digest the three concepts as a fundamental departure point for fixing your master data:

There is no question that addressing the issue of material master data is complex and daunting, but you will have to begin somewhere. In the interests of getting back to basics, I’d propose you digest the three concepts as a fundamental departure point for fixing your master data:

- One solution does not fit all,

- Each material will require individual attention (I’ll write about this in an upcoming blog), and

- Your approaches to both Static and Dynamic Master data - they are different (more about this in another blog).

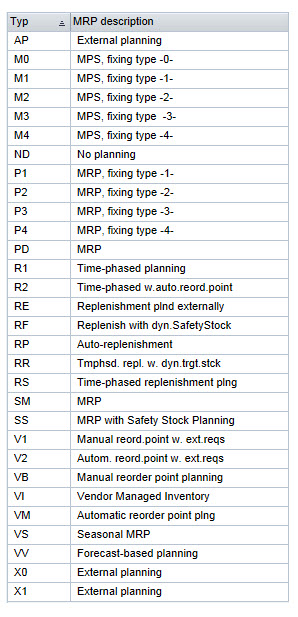

SAP have built a variety of different stocking strategies into the four MRP views you find in a material master and when combined through a structured and thought-out approach, will significantly improve not only the quality of your master data, but the outputs of your MRP. For the most part I see companies typically sticking to one set of rules across all materials, implying that all materials, articles or spares behave in exactly the same way – I do not believe that this is the case. One way to test if your implementation went this route is to figure out the spread of MRP Types that you use. From the screen shot on the right you can see that SAP has built around 30 standard MRP Types into the system. Most companies use only one or two. If this is the case in your company, then you have inadvertently adopted a “One Solution Fits All” inventory management philosophy.

There are some standard, quick and easy reports you can use to figure out the spread of MRP Types your company uses across your all your inventory. Your SAP support partner or IT department should be able to guide you to these. Understanding this spread is a good starting point to begin addressing the multitude of other possible master data settings. If you only have one or two, then you have some work to do!

Originally published on May 20, 2014